In my previous post I included a photo of my Millers Falls drill press in action. Since several readers made comments about this tool, I thought I would do a post with additional information and images.

The Millers Falls #23 drill press has a built-in clamp for attaching to a bench. Since my bench top is too thick for this clamp, I hold a short section of 2x4 in a vise and clamp the press to that. Note that for the purposes of taking pictures, I did not clamp the tool in the same orientation that I would for actually using it. Your right hand powers the drill, while your left uses a compound lever to do the pressing. It works great, except that doesnt leave a hand to hold the work piece. It looks like it originally came with a dedicated clamp (see catalog image below), but mine is missing in action. I might try to build some kind of small, adjustable fence to use with this drill press - its a little awkward, and slow, to clamp small pieces to the platform.

Your right hand powers the drill, while your left uses a compound lever to do the pressing. It works great, except that doesnt leave a hand to hold the work piece. It looks like it originally came with a dedicated clamp (see catalog image below), but mine is missing in action. I might try to build some kind of small, adjustable fence to use with this drill press - its a little awkward, and slow, to clamp small pieces to the platform. Heres a page from Millers Falls 1939 catalog that lists this drill press. I found this over at Rose Antique Tools, a great site with loads of old tool catalogs in pdf format - check it out. They sell old tools (and new) as well.

Heres a page from Millers Falls 1939 catalog that lists this drill press. I found this over at Rose Antique Tools, a great site with loads of old tool catalogs in pdf format - check it out. They sell old tools (and new) as well. Surprisingly, this is one of the few old tools that I didnt have to travel to the lower 48, or to eBay, to purchase. I actually found this in a local shop - which is almost unheard of for me. The information they had was that it came down from Barrow where an Alaskan Native artist used it to make cribbage boards.

Surprisingly, this is one of the few old tools that I didnt have to travel to the lower 48, or to eBay, to purchase. I actually found this in a local shop - which is almost unheard of for me. The information they had was that it came down from Barrow where an Alaskan Native artist used it to make cribbage boards.

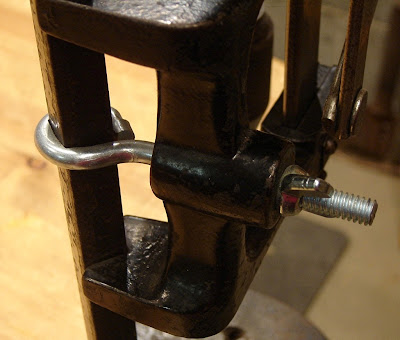

It was in great shape, and a total score. It only needed one small repair, to be shop ready. The clamp that attaches the whole mechanism to the vertical support, and thereby also controls the height adjustment of the drill press, was worn out. It could no longer clamp securely to the bar, so I replaced it with a clamp fashioned by filing the inside of an eye bolt to a square shape. After that it was just a matter of cleaning it up and oiling it.  This is by no means a required tool for a hand tool only shop. Ive had it for at least two years, and only recently used it on a project. With practice, you can drill perpendicularly to a surface just using a hand drill (Millers Falls also made some excellent hand drills - I love my #2). When I have needed to drill consistent, angled holes (as for my spokeshave and brace racks) I made a simple jig by boring one hole at the desired angle and then using that to guide the bit on all subsequent holes. In fact, if you look closely at this picture from the previous post, you can see that I used that piece of 2x4 for just that purpose in the past (total coincidence).

This is by no means a required tool for a hand tool only shop. Ive had it for at least two years, and only recently used it on a project. With practice, you can drill perpendicularly to a surface just using a hand drill (Millers Falls also made some excellent hand drills - I love my #2). When I have needed to drill consistent, angled holes (as for my spokeshave and brace racks) I made a simple jig by boring one hole at the desired angle and then using that to guide the bit on all subsequent holes. In fact, if you look closely at this picture from the previous post, you can see that I used that piece of 2x4 for just that purpose in the past (total coincidence).

Rabu, 06 April 2016

Millers Falls Drill Press No 23

Langganan:

Posting Komentar (Atom)

0 komentar:

Posting Komentar